CRNN FACILITIES

Vision : Creation of a Center of Excellence for interdisciplinary research in Nanoscience and Nanotechnology, including Physical, Chemical and Biological Sciences

Rationale : In recognition of its glorious contribution for the last 150 years, The Honorable Finance Minster, Govt. of India, allocated to the University of Calcutta Rs 100 Crores for pursuing research in emerging sciences and technologies of national importance. The University decided to utilize this fund for the creation of a Center for Research in Nanoscience and Nanotechnology, to meet global challenges in this area.

Thrust Areas : The University has decided to utilize its vast and divergent expertise in Physical, Chemical, Biological Sciences and Technology, and pursue a truly synergetic approach towards meeting the goals of the CRNN. The major thrust will be in the area of nanofabrication guided by requirements of high degree of control at the nanometer scale. In addition, characterization of nanoscale materials in order to fully understand their novel properties is essential. Such structures will be integrated into macro-scale products through hierarchical integration processes. Side by side, powerful and versatile computational facilities are also essential for the proper understanding of the various physical phenomena. Highly efficient manufacturing processes are also envisaged, reducing material consumption and minimizing environment cost for new energy efficient products. Thus establishment of a viable technology transfer mechanism is therefore also a prime concern.

A: Semiconductor Clean Room

A: Semiconductor Clean Room

Clean Rooms’ are specially constructed, environmentally controlled enclosed spaces where the concentration of airborne particles along with temperature and humidity can be kept within specified limits. While 'Clean Rooms' are essential for fabricating nano-structure devices, integrated circuits (ICs), and so on, these are also used in medicine industry to create an environment free from bacteria, viruses, or other pathogens.

The 'Clean Room' specification for dust particles is defined according to the maximum allowable particle size (diameter), and also according to the maximum allowable number of particles per unit volume. A Class 100 'Clean Room', for example, would not contain more than 100 particles bigger than 0.5 micro meter in a cubic foot of air. The CRNN clean room facility consists of a Class 100 region with an area of 600 Sq-ft, a Class 1000 region with an area of 1500 Sq-ft, total of a Class 10, 000 region with an area of 2500 Sq-ft and a Class 100, 000 service corridor area amounting to approximately 2000 Sq-ft.

The 'Clean Room' accessories are placed in different vertical layers. The top mezzanine floor has all the Air Handling Units (AHU), BMS, and UPS for emergency power supply. All ducting for air circulation and process gas exhaust are passed in the level in between the mezzanine floor and 'False Ceiling' about the process area. The chiller, DG set, and Scrubber are placed in the adjacent 'Utility Building'. The Biological and Chemical Blocks are placed by the side of the Physical Processing and Metrology and Material growth Blocks.

B: Nanofabrication Facilities

B: Nanofabrication Facilities

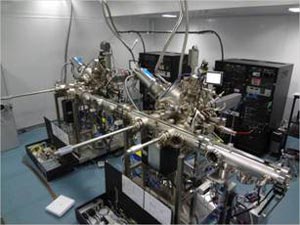

A Dual Chamber Molecular Beam Epitaxy system has been procured for fabrication of device structures based on the Si-Ge and the Al-In-Ga-N group of materials. These systems are capable of deposition of films with high degree of accuracy in alloy composition and doping levels with thickness control at the monolayer level.

For the fabrication of nanoscale electronic devices, a Cross-beam system has been installed. In addition to an electron beam system which will carry out lithography at the nanometer scale, it features a Focused Ion Beam system which can etch as well deposit materials with line widths of ~20nm. In order to integrate the nanoscale structures within the macro-scale electronic devices, a series of equipment such as mask aligners have been installed for carrying our standard photolithographic and other device fabrication steps. A reactive ion etching system is also about to be installed shortly, while the other fabrication equipment will be considered at a later stage.

C: Characterization facilities

It is equally important to carry out structural, morphological and chemical analysis of fabricated nano-materials. The CRNN has procured a transmission electron microscope with EELS facility for achieving this goal. In addition, a Field Emission Scanning Electron Microscope has been configured with a Cathodoluminescence system to carry out luminescence measurement at the nanometer scale. Since it is important to test biological materials at the natural state, a Scanning Electron Microscope capable to operation at near ambient pressures has been installed. This system is also capable of investigating materials at cryogenic temperatures.

A series of scientific instruments have also been procured to investigate the optical and magnetic properties of materials. These include a SQUID VSM which is capable to investigate samples at cryogenic temperatures. Optical characterization is being carried out using spectrophotometers, ellipsometers, FTIR imaging facilities, and at the CRNN dark room which is capable of versatile measurements of luminescent and other optical as well as electronic properties of bulk films and nanostructures at room and low temperatures.

For research in biomedical areas, the CRNN has undertaken a joint research effort with BD Bioscience and a series of scientific instruments have been installed under this program. This include an ultra centrifuge and extensive cell imaging facilities. In addition, a cell culture facility has also been established.

Academic programs

Academic programs

The CRNN, CU offers a Ph D. program in Nanoscience and Nanotechnology, The center also has a library and well equipped seminar rooms for technical presentations, and a number of workshops and symposia, in various branches of science and technology, have already been held using these facilities