MOLECULAR BEAM EPITAXY

FOCUS OF RESEARCH

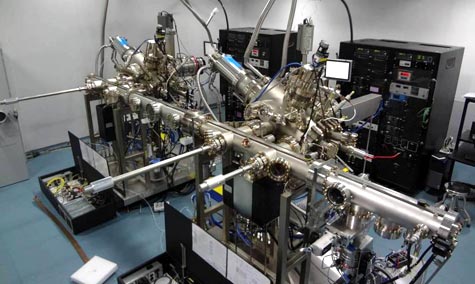

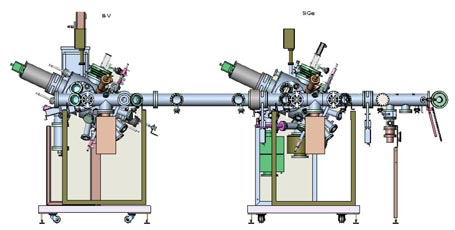

The MBE system at the CU-CRNN is a dual chamber one, with one chamber dedicated to the deposition of Si-Ge system, while the other for III-Nitride materials. For Chamber 1, the sources for Si, Ge, Sb, and B are present, along with an advanced filament source that is configurable for deposition of thin silicon films with any doping level. This chamber will be used for the deposition of advanced C-MOS structures, SiGe based photodetectors, HBTs, etc.

The Chamber 2 houses sources for Gallium, Aluminum, Indium, Nitrogen, Ammonia, Silicon and Magnesium. This will be employed for the growth of III-Nitride materials, which are used in development of light emitting diodes, lasers and high power high speed electronic discrete devices. The ultimate goal of the research is the integration of the two class of devices, optoelectronic and Silicon MOS, on to the same wafer.

EQUIPMENT DETAILS

| Chamber | Sources |

| Si-Ge | Germanium |

| Si-Ge | Boron |

| Si-Ge | Antimony |

| Si-Ge | Slicon e-beam |

| Si-Ge | Silicon SUSI source |

| III-Nitrides | Gallium |

| III-Nitrides | Aluminum 1 |

| III-Nitrides | Aluminum 2 |

| III-Nitrides | Indium |

| III-Nitrides | Silicon (dopant) |

| III-Nitrides | Magnesium |

| III-Nitrides | RF Nitrogen Plasma |

| III-Nitrides | Ammonia Injector |

SCHEMATIC: DUAL GEN-930 SYSTEM FROM VEECO

High Pressure Homogenizer (HPH)

FOCUS OF RESEARCH

It is an electric bench-top laboratory High Pressure Homogenizer (HPH) which can be used to deliver in providing small, uniform and evenly distributed particles or in cell disruption. Sample size is as small as 20 ml (12 ml with option). Pressure can be as high as 45,000 PSI to match industrial specification. Its application range includes:

• Preparation of emulsions and dispersions;

• Cell Rupturing;

• Deagglomerations In broader sense the instrument can -

• help in producing nano-particles such as sunscreens, targeted and controlled release drug delivery systems, transparent coatings, contrast agents, ink, etc. - utilize nano-particles in a liquid vehicle. Its dual feed and dual Jet options allow for particle size reduction of powders and hard materials.

• help in producing emulsions which are stable mixtures of oil and water, with one of them dispersed into the other in the form of fine droplets. There are "oil-in-water" emulsions, such as salad dressing and skin care creams, and "water-in-oil" emulsions, such as margarine and nutraceuticals.

• help in producing suspensions. Many applications, such as injectible medications and fuel cells require suspensions of nanoparticles in an aqueous medium.

• help in cell rupture or disruption, where the cell envelope is physically broken, releasing all intercellular components into the surrounding medium. More...